StarLITE®R for CSD

Ultimate bottle quality for up to 100% rPET

When aseptic matters

The perfect partner

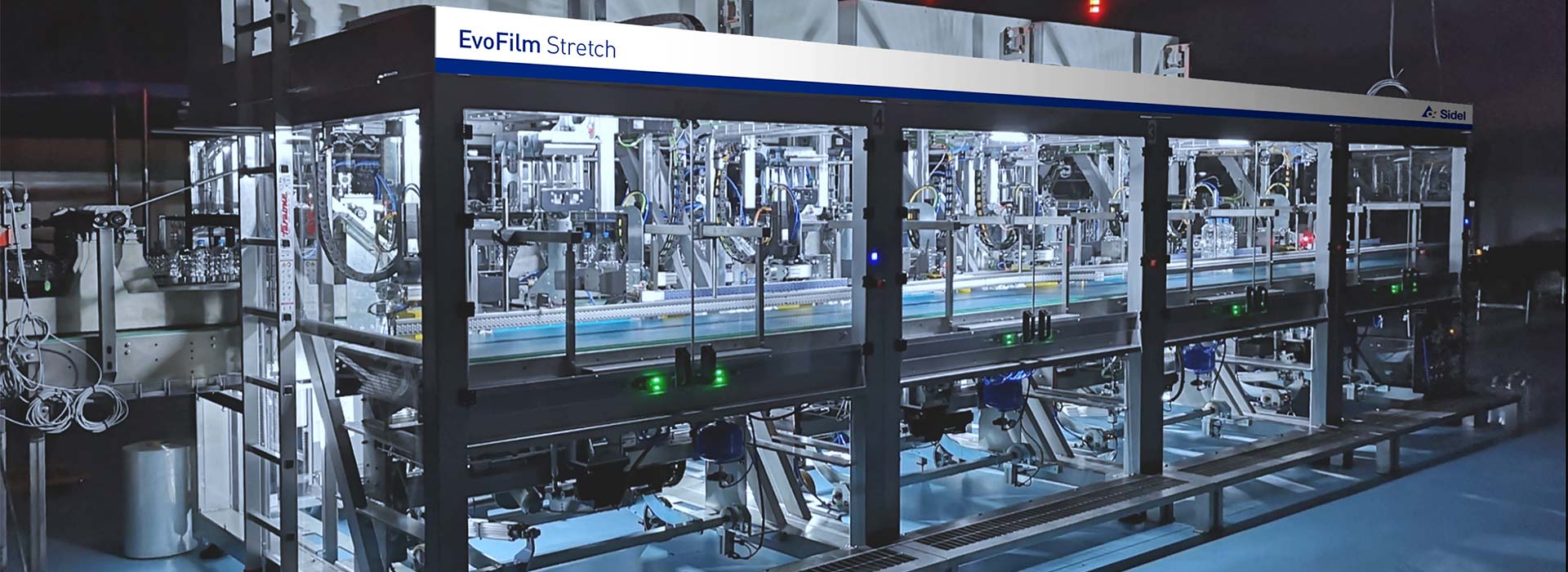

EvoFilm Stretch

Plastic film and energy consumption minimized for packs and multipacks

RoboAccess_Pal S

Finding high palletizing performances in a compact footprint

.jpg)